|

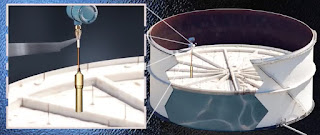

| Floating Roof Tank Spill Prevention (Drexelbrook) |

|

| Drexelbrook's Intellipoint |

The challenges to reliably detect a high level condition on a floating roof tank are long sensor length requirements, and the variability of what is being measured. The floating roof may be dry in which case you need to detect the position of the physical metal roof. Or there may be a few inches of rain water or petroleum liquids on the roof. Measuring instruments need to determine very accurately, usually within a few millimeters, when the position of the floating roof has reached a high level alarm condition.

Drexelbrook's Intellipoint, with its unique floating roof probe, can accurately detect and alarm on the position of the floating roof or the presence of liquid under all these conditions. The safety Intellipoint is a SIL2 fully certified RF admittance point level switch with uncompromising reliability for the most demanding applications. Drexelbrook has almost 60 years of RF admittance technology experience and is proud to offer this specialized product as the latest in its award-winning portfolio for the level market.

Product features include:

- Adjustable up to 15 feet, or 4.6 meters, to accurately control the alarm point.

- A trip point accuracy of a few millimeters.

- Fully SIL2 certified to IEC61508.

- Worldwide hazardous area approvals .

- Meets overfill protection standards API2350.

- A floating roof tank probe that is unique in the industry.