One of the most difficult and critical applications is measuring the high alarm or potential overfill condition on a floating roof tank containing liquid petroleum products such as crude oil or refined products such as fuel. It normally is comprised of a cylindrical steel tank equipped with an internal or external floating roof, that floats on the surface of the stored liquid. Floating roof tank systems are especially beneficial in eliminating the evaporative losses of the liquids. As opposed to a fixed roof tank there is no vapor space in the tank. This helps to reduce risk in highly explosive vapor environments. This is an extremely high cost of failure application, and one in which only the safest and most trusted products are accepted.

Safe operation of the tank farm relies on critical real time continuous level measurements of the liquids in the tank, as well as detecting when a high level condition exists. Products used in this application are typically required to meet the API 2350 Overfill Protection Standards, as well as SIL Safety Integrity Level performance standards to IEC 61508.

The challenges to reliably detect a high level condition on a floating roof tank are long sensor length requirements, and the variability of what is being measured. The floating roof may be dry in which case you need to detect the position of the physical metal roof. Or there may be a few inches of rain water or petroleum liquids on the roof. Measuring instruments need to determine very accurately, usually within a few millimeters, when the position of the floating roof has reached

The

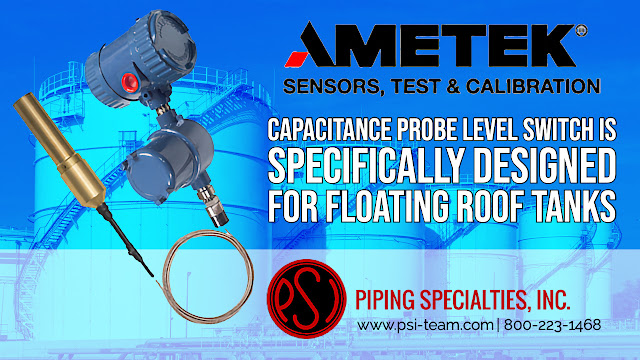

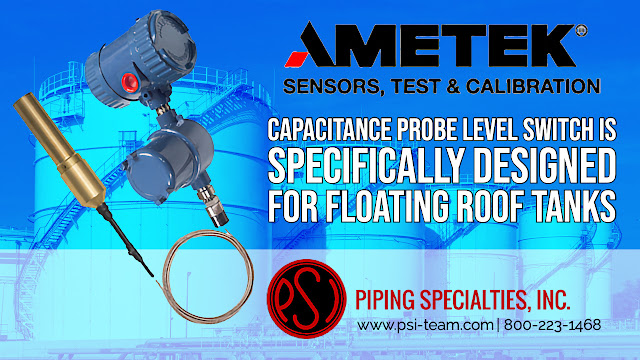

Drexelbrook SIL IntelliPoint capacitance probe level switch is specifically designed for Floating Roof Tanks (internal and external roofs) with a flexible brass level sensing probe. The level probe sensing element is field adjustable for lengths up to 15' (4.6 m). Electronics are designed to meet API 2350 Overfill Protection.

This level measurement system is specifically designed for spill prevention in floating roof tanks (internal and external roofs) using the IntelliPoint level switch with a flexible level sensing element for ease of installation (model 700-0005-595).

This level measurement system meets API 2350 regulations. It is ideal for use in safety related systems with requirements for functional safety for SIL2 in accordance to IEC61508-2, ed2, 2010 (Exida).

To prevent false alarms this level measurement system automatically recognizes and ignores coatings and is supplied with continuous self-test monitors circuits and sensing elements to detect faults.

A dual compartment housing separates the customer wiring from the sensing element and operating circuits. The encapsulated power supply/terminal block design eliminates the possibility of damage caused by moisture in the conduit.

The Floating Roof Tanks system comes with field adjustable lengths from 1' to 15' (0.3 to 4.6 m).

The system is based on our Manual Certify principle which allows the entire system to be manually tested without removing the sensor from the tank. The Manual Certify test checks that the Auto Verify circuits are operating and confirms the probe and cables are properly connected. Furthermore, the Manual Certify feature allows the electronics to sense changes in the probe that simulate contact with the media or floating roof. This provides the user with a method to ensure working performance without having to climb the tank.

No calibration or setpoint adjustments are required.

Key Features

- Loop or Line Powered

- Wetted Parts: 316SS 3/4" NPT Mounting, 3/16" FEP insulated flexible and adjustable cable, non-sparking brass sensor.

- Automatic and local or remote manual test functions ensure proper system operation.

- One system fits most floating roof tank applications, reducing field spans

- Adjustable insertion lengths up to 15' (4,6m)

- Excellent trip point accuracy over a wide range of medias and tank roof

Piping Specialties / PSI Controls

800-223-1468