Piping Specialties Inc. (PSI) is one of the northeast's largest suppliers of valves; process controls/instrumentation, and engineered mechanical specialties. Industries served: Power Generation, Pulp/Paper, HVAC, Water/Wastewater, Food/Beverage, Life Sciences, Chemical/ Process, Semiconductor. For more information visit PSI-Team.com or call 800-223-1468.

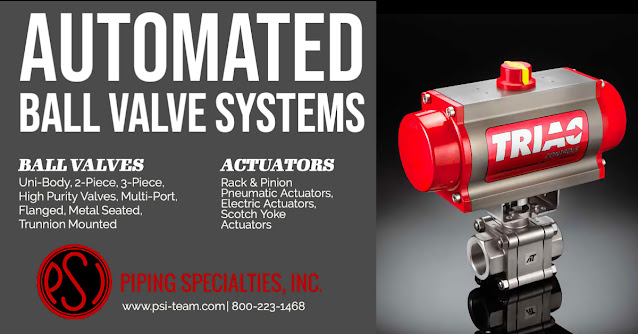

Piping Specialties is Your Preferred Ball Valve Automation Specialist in New England

Extremely Durable 4.5 Inch Process Gauges

Series PT45P Features

- Safety Pattern Design

- Solid Front/Blowout Back Safety Case

- All Stainless Steel Internal Parts

- Internal Overload and Underload Stops

- Field Fillable Case

- Micro-Adjustable Pointer with Floating Zero

- ASME B40.100 Design

- NACE MR-0175 and MR-0103 Compliant

HABONIM 50 Series Top Entry Cryogenic Ball Valves

Due to its unique one-piece body structure, the HABONIM Series 50 Top Entry Valve is the ultimate answer for pipeline integrity on the one hand and inline serviceability on the other.

The 50 Series of HABONIM bidirectional top entry cryogenic ball valves are a modern adaption of a trunnion ball valve with top entry construction and patent-pending new design elements.

The main challenge for an assembly or maintenance team with a standard top entry valve is usually the complexity of assembly and disassembly of the valve inner parts, the time-consuming operation, and the requirement for special equipment and jigs.

All of these problems are addressed and solved by HABONIM's Series 50 top entry valve design.

Upon removing the valve bonnet screws, the crew has immediate access to the valve's interior parts, allowing for thorough maintenance and replacement of all inner components and sealing. This one-of-a-kind design provides for complete valve renovation inline without the need to remove any insulation pieces.

One Double Piston Effect (DPE) dynamic seat is used in the patent-pending design, allowing bidirectional sealing under the full differential and a relatively simple design with few parts and no closed cavities. These qualities provide all of the advantages of a ball valve's high flow (Cv) with no restriction on flow direction or sealing, as well as a safer cryogenic construction.

When installed, a patent-pending supplementary optional body extender raises the valve's bonnet above piping insulation, allowing the valve to be maintained without removing the insulation or without special valve insulation boxes.

The valve's revolutionary design allows for quick inline serviceability with minimal effort and inexpensive equipment for valve dismantling, replacement, and reassembly.

For more information in New England, contact Piping Specialties. Call 800-223-1468 or visit https://psi-team.com.

Food Industry Batch Level Control

- 3A designed sanitary sensing elements

- No moving parts

- 3 control points on one vertical sensing element

- Cote-Shield circuitry eliminates false alarms due to coatings

- Designed to endure Clean In Place (CIP) demands

All Stainless Steel Ball Valve and Actuator Systems

Stainless steel pneumatic actuators are available in spring return, double acting, fail open, and fail close configurations. A corrosion resistance surface - resistance to most corrosive materials - is one of the advantages of using a stainless steel actuator. The stainless steel pneumatic actuator is excellent for heavy-duty automation, especially in corrosive environments. Stainless steel actuators with a durable stainless steel body manufactured to NAMUR standards continue to perform in the harshest environments.

Piping Specialties' stainless steel actuated ball valves provide exceptional accuracy and dependability in flow control and open/close operations, critical in manufacturing, chemical, oil & gas, wastewater, processing, and other applications.

Piping Specialties is committed to providing the most suitable valve for your application. For more information about stainless steel valves, call 800-223-1468 or visit https://psi-team.com.