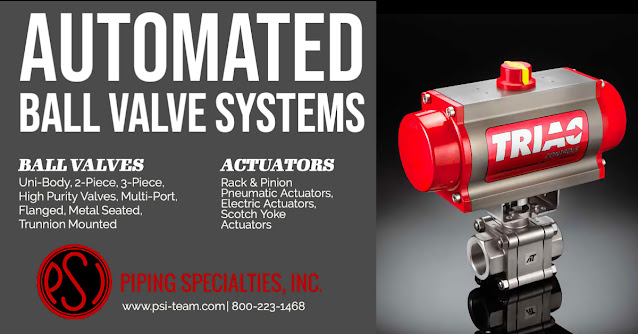

Piping Specialties Inc. (PSI) is one of the northeast's largest suppliers of valves; process controls/instrumentation, and engineered mechanical specialties. Industries served: Power Generation, Pulp/Paper, HVAC, Water/Wastewater, Food/Beverage, Life Sciences, Chemical/ Process, Semiconductor. For more information visit PSI-Team.com or call 800-223-1468.

Piping Specialties is Your Preferred Ball Valve Automation Specialist in New England

All Stainless Steel Ball Valve and Actuator Systems

Stainless steel pneumatic actuators are available in spring return, double acting, fail open, and fail close configurations. A corrosion resistance surface - resistance to most corrosive materials - is one of the advantages of using a stainless steel actuator. The stainless steel pneumatic actuator is excellent for heavy-duty automation, especially in corrosive environments. Stainless steel actuators with a durable stainless steel body manufactured to NAMUR standards continue to perform in the harshest environments.

Piping Specialties' stainless steel actuated ball valves provide exceptional accuracy and dependability in flow control and open/close operations, critical in manufacturing, chemical, oil & gas, wastewater, processing, and other applications.

Piping Specialties is committed to providing the most suitable valve for your application. For more information about stainless steel valves, call 800-223-1468 or visit https://psi-team.com.

Ball Valves Used for Black Liquor in Pulping Kraft Process

Many toxic, corrosive, and reactive chemicals are used in pulp and paper mills in chemical pulping. This incredibly hostile environment requires well-engineered automatic valve systems and durable valve actuators, spring units, and positioners.

Suppose you understand how paper is made and what chemicals are usually used in the atmosphere. In that case, you can instantly understand why special consideration is required for valve and actuator selection.

In the early stage of paper production, digesters combine high heat and a heavy alkaline liquid called "white liquor" to convert wood chips into a pulp during separation from wood chips. White liquor (mainly sodium hydroxide and sodium sulfide), process water, heat, and pressure are used to separate wood chips into lignin and cellulose fibers. The white liquor breaks down the lignin (the substance that binds the wood fiber together) in wood chips. The resulting combination of water and spent white liquor produces "black liquor." This liquid pulp residue mixture made up of lignin and hemicellulose, and inorganic compounds such as sodium hydroxide and sodium sulfide is toxic. Another by-product of this process is Hydrogen Sulfide, a toxic, corrosive, and flammable gas.

Effects on Ball Valves

In piping and ball valves, managing these process chemicals and by-products is difficult. Pipe diameters range from 2"-10", but the most common sizes are 4", 6" and 8." Usually, these processes are ANSI / ASME Class 150 and ANSI / ASME Class 300, the most common end connection being 150 # and 300 #. Process temperatures are usually high, between 250 ° F and 350 ° F. The valve body and end connection materials are generally 316 stainless steel, but you'll also find carbon steel requested. Applications can include manual lever, gear operators, pneumatic actuators, and electrical actuators in valve assemblies.

The most concerning issue is the sticky molasses-like liquor builds upon the ball valve face and contaminates the back seat spaces, inducing strong internal clearance forces, resulting in valve lock-up over long static periods. A superior ball valve seat design from A-T Controls addresses the viscous material problem.

A-T Controls developed a solution for this extreme pulp and paper service and black liquor service with notable improvements to their FMS series. This valve incorporates a "scraper seat" feature that eliminates the molasses-like residue baked on the ball's face and eliminates valve lock-up. The addition of Aflas ® o-rings seal the seat cavity from media build-up, and a Venturi hole in the ball is also provided.

Typical black liquor ball valve from A-T Controls:

- Series: A-T Controls FMS

- Sizes: ½" -8"

- Rating: ANSI/ASME Class 150/Class 300 with 150# and 300# flanges, API 607.

- Ball and Seats: Tungsten Carbide coated metal scraper seats (Aflas® o-rings and Venturi Ball for black liquor service.)

Please consult a Piping Specialties Applications Engineer for material selection for your black liquor application. This information is a guideline, and customers are solely responsible for construction materials, preparation of the valves for service, and lubricants being compatible with their black liquor application.

For a free consultation, call Piping Specialties at 800-223-1468 or visit their website at https://psi-team.com.

What Are Trunnion Mount Ball Valves?

|

| Trunnion ball valve design. Trunnions highlighted. |

Although there are many varieties of seat designs, body styles, and flow patterns, ball valves can be separated in to two main groups, distinguished by a primary design element - the mounting method of the valve ball.

The two groups are:

- Floating ball

- Trunnion mounted ball

Trunnion mount valves, on the other hand, employ a "trunnion" in their design. A trunnion is a pin, or a pivot, forming one of a pair on which ball is mechanically connected and supported. The valve shaft and the trunnion connect at the top and bottom of the valve and create the vertical axis of rotation for the ball. The trunnion also prevents the ball from moving or shifting with changing pressures.

Due to their structural integrity, trunnion mount ball valves are generally well suited for all pressure ranges and valve sizes. Their design is used by many manufacturers for severe service. They provide excellent sealing properties over an extensive range of temperatures and pressures. Trunnion mount valves are available in both full and reduced bore designs with a wide range of materials, sizes, and pressure classes offered. The vast range of sizes, styles, pressure classes, and materials together with conformance to ANSI, API, and NACE specifications make these valves suitable for virtually all industrial, petrochemical, refinery, and oil and gas services. Finally, there may be an advantage to actuate trunnion ball valves due to lower torque requirements compared to similar floating ball valves whose torque increases with increasing flow pressure.

For more information on floating ball or trunnion mount ball valves, contact Piping Specialties, Inc. at 800-223-1468 or visit https://psi-team.com.

MOGAS Severe Service Ball Valve "Mate Lap" Seal Demonstration

MOGAS valves have outperformed others worldwide in some of the most severe service conditions, including: Extreme temperatures; High pressures; Abrasive particulates; Acidic products; Heavy solids build-up; Critical plant safety; Large pressure differentials; Velocity control; Noise control.

What Are Industrial Ball Valves?

|

| Internal view of a ball valve (MOGAS) |

On a full port valve, the port is the same size as the pipeline, resulting in a better flow profile and no restriction or pressure drop. A full ported ball valve, with better flow coefficients, comes at a higher price. In many application they are necessary because a reduction in diameter, or the resulting change in flow, can be detrimental.

The reduction in a standard port valve is one pipe size smaller than the pipe connected to the valve, resulting in restricted flow and increased velocity through the valve.

|

| 2-piece and unibody ball valves (Flo-Tite) |

non-linear flow characteristic. Characterizing the port with a special shaped orifice can improve the valve linearity and provide good control. V-port ball valves incorporate a machined "V" in the seat around the outlet side of the valve. The "V" provides a more controllable flow pattern and is desirable when ball valves are used as control valves.

A cavity filled ball valve is used in applications where cleanliness or sanitary conditions exist. Any voids, gaps or spaces between the ball, seat and stem that allow bacteria or contaminates to accumulate are filled. The proper cavity filler material is selected consistent with the process media, application and level of cleanliness required. Cavity fillers eliminate the spaces and voids where contaminants accumulate and provides easy "flushing" (cleaning) of the valve.

In a trunnion mounted ball valve, the valve stem is mechanically attached to the ball. Trunnion mounted valves are mostly used in applications on large diameter gas and oil pipelines and at high pressures.

Most ball valves however, are designed with a “floating ball” and not held mechanically in place by a trunnion. This allows the ball to be "pushed" slightly downstream and seal itself better against the seat. One advantage to this design is that a valve using a floating ball, and fitted with metal seats, can be used for "fire-safe" applications. This means that if the valve is subject to high temperatures, such as those presented in a fire, the "soft" part of the seat will melt away, and allow the ball to secure itself against the metal seat, and thus not allow material to pass and potentially feed the fire.

For best service life and optimum safety, please review your application with a qualified ball valve applications consultant prior to specifying an industrial ball valve.

Mogas FlexStream: Rotary Control Technology for Severe Service Applications

|

| 1) Diffusion element splits and aligns the flow. 2) The control element reduces the flow velocity. |

For applications requiring high rangeability, ideal flow control is available by varying the combination of control area and open area, within the trim. The control area determines the amount of bore filled with multi-stage paths, and is used for higher pressure drop lower flow conditions. The open area determines the amount of unrestricted flow, and is used for lower pressure, drop higher flow conditions. This custom fill characterization can vary from 30 to 100 percent, depending on flow conditions, pressure drop, noise level, and outlet velocity required. Precise process and velocity control are achieved at every stage of valve opening, with exceptionally high rangeability in a single control valve.

For gas and steam applications, extreme noise and vibration are reduced or eliminated. The patented FlexStream technology expands upon the strengths of Mogas quarter turn ball valves to offer application-specific trim engineered for high delta-P applications, replaceable control element design, greater Cv per inch compared to the competition, and a smaller dimensional envelope in a traditional control valve.