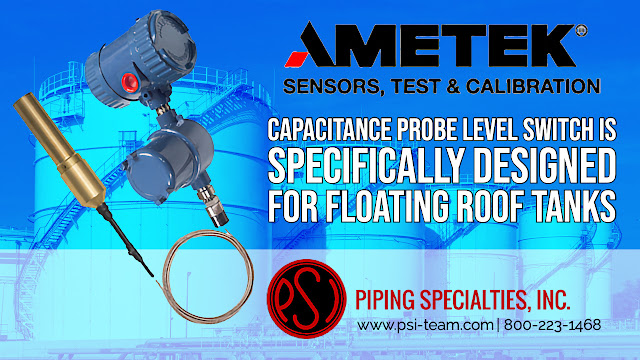

- Loop or Line Powered

- Wetted Parts: 316SS 3/4" NPT Mounting, 3/16" FEP insulated flexible and adjustable cable, non-sparking brass sensor.

- Automatic and local or remote manual test functions ensure proper system operation.

- One system fits most floating roof tank applications, reducing field spans

- Adjustable insertion lengths up to 15' (4,6m)

- Excellent trip point accuracy over a wide range of medias and tank roof

Piping Specialties Inc. (PSI) is one of the northeast's largest suppliers of valves; process controls/instrumentation, and engineered mechanical specialties. Industries served: Power Generation, Pulp/Paper, HVAC, Water/Wastewater, Food/Beverage, Life Sciences, Chemical/ Process, Semiconductor. For more information visit PSI-Team.com or call 800-223-1468.

SIL Level Switch Is Specifically Designed for Floating Roof Tanks

High-performance and Resilient Seated Butterfly Valves for Commercial and Industrial Applications

A butterfly valve has a disc that is in the fluid flow path. In the most common style of butterfly valve, the disc revolves around a central axis, the stem, via a 90-degree arc from parallel to the flow direction (open) to perpendicular to the flow direction (closed). Butterfly valves have a straightforward design with few moving components, making them simple to repair and maintain. The valve has four main parts: the body, the stem, the disk, and the seat.

The butterfly disk is always in the flow path, but its thin profile has little effect on flow. Butterfly valves are popular because they provide tight shut-off, are available in various materials and sizes, and may be easily automated using a variety of quarter-turn electric and pneumatic actuators.

You'll find butterfly valves in a wide range of industrial applications, from managing the flow of water to handling far more hazardous industrial fluids. Many industries use butterfly valves, including water treatment, chemical processing, pulp, paper manufacturing, food processing, power generation, etc.

There are two primary classifications of butterfly valves:

- High-performance butterfly valves (HPBV)

- Resilient seated butterfly valves

High-performance butterfly valves include carbon or stainless steel bodies with Teflon seats and can withstand more significant pressures and temperatures. Resilient seated valves usually feature ductile iron or aluminum bodies and operate at lower pressures and temperatures.

Butterfly valve bodies are available in two mounting styles: lug and wafer. Lug bodies include cast-in lugs with bolt hole designs that match pipe flanges. A wafer body valve does not have a mounting hole pattern, and mounting is facilitated by sandwiching the valve between two pipe flanges, with mounting bolts around the valve body. Wafer-style bodies are less costly. An advantage to lug body valves is their use as a dead-end valve, whereas wafer valves are unsuitable for this service.

The stem is a one or two-piece shaft that keeps the disk in place and provides the rotational torque that allows the disk to open and shut. The stem of resilient seated valves has protection from the process media by packing rings, allowing for a more cost-effective solution to regulate the valve's application to various potentially corrosive media. High-performance butterfly valve stems come into touch with process media and must be media suitable.

The disk is the valve component that comes into direct contact with the process medium and regulates flow. Disks are available in various materials and optionally come with corrosion-resistant polymer coatings. Some butterfly valves include contoured disks that are carefully aligned with the stem to increase flow control, modify torque needs, or give the valve a longer life.

A resilient seated valve closes via an "interference fit," which means the disk forces itself into the seat. The seat is the soft substance (polymer elastomer) including Buna-N and Nitrile, and should be specified depending on the process medium involved.

High-performance butterfly valves use an interference fit as well, but with significantly tighter tolerances, but also ensure tight seating with assistance from upstream pressure. PTFE or RTFE are the most often used materials for HPBV seats. Metal seats on HPBVs accommodate more significant pressure and temperature applications.

Like other valves, butterfly valves have applications in which they outperform. To apply the optimum solution to your flow control applications, combine your process knowledge with your product knowledge with the application skills of a proven valve engineering professional. Contact Piping Specialties, Inc. for more information about industrial valves. Visit https://psi-team.com or call 800-223-1468.

Industrial Thermowell Process Connection Types

Water Cut Meters from Drexelbrook

Water cut meters measure the water cut (or BS&W) of oil flowing from a well, a separator, crude oil transfer in pipelines, and tanker loading.

Piping Specialties is Your Preferred Ball Valve Automation Specialist in New England

Contact Piping Specialties / PSI Controls with your next automated ball valve requirement.

Extremely Durable 4.5 Inch Process Gauges

Series PT45P Features

- Safety Pattern Design

- Solid Front/Blowout Back Safety Case

- All Stainless Steel Internal Parts

- Internal Overload and Underload Stops

- Field Fillable Case

- Micro-Adjustable Pointer with Floating Zero

- ASME B40.100 Design

- NACE MR-0175 and MR-0103 Compliant

HABONIM 50 Series Top Entry Cryogenic Ball Valves

Due to its unique one-piece body structure, the HABONIM Series 50 Top Entry Valve is the ultimate answer for pipeline integrity on the one hand and inline serviceability on the other.

The 50 Series of HABONIM bidirectional top entry cryogenic ball valves are a modern adaption of a trunnion ball valve with top entry construction and patent-pending new design elements.

The main challenge for an assembly or maintenance team with a standard top entry valve is usually the complexity of assembly and disassembly of the valve inner parts, the time-consuming operation, and the requirement for special equipment and jigs.

All of these problems are addressed and solved by HABONIM's Series 50 top entry valve design.

Upon removing the valve bonnet screws, the crew has immediate access to the valve's interior parts, allowing for thorough maintenance and replacement of all inner components and sealing. This one-of-a-kind design provides for complete valve renovation inline without the need to remove any insulation pieces.

One Double Piston Effect (DPE) dynamic seat is used in the patent-pending design, allowing bidirectional sealing under the full differential and a relatively simple design with few parts and no closed cavities. These qualities provide all of the advantages of a ball valve's high flow (Cv) with no restriction on flow direction or sealing, as well as a safer cryogenic construction.

When installed, a patent-pending supplementary optional body extender raises the valve's bonnet above piping insulation, allowing the valve to be maintained without removing the insulation or without special valve insulation boxes.

The valve's revolutionary design allows for quick inline serviceability with minimal effort and inexpensive equipment for valve dismantling, replacement, and reassembly.

For more information in New England, contact Piping Specialties. Call 800-223-1468 or visit https://psi-team.com.