MOGAS valves have outperformed others worldwide in some of the most severe service conditions, including: Extreme temperatures; High pressures; Abrasive particulates; Acidic products; Heavy solids build-up; Critical plant safety; Large pressure differentials; Velocity control; Noise control.

Piping Specialties Inc. (PSI) is one of the northeast's largest suppliers of valves; process controls/instrumentation, and engineered mechanical specialties. Industries served: Power Generation, Pulp/Paper, HVAC, Water/Wastewater, Food/Beverage, Life Sciences, Chemical/ Process, Semiconductor. For more information visit PSI-Team.com or call 800-223-1468.

MOGAS Severe Service Ball Valve "Mate Lap" Seal Demonstration

The video below demonstrates the effectiveness of the MOGAS "Mate Lap" seal provided on MOGAS severe service ball valves.

MOGAS valves have outperformed others worldwide in some of the most severe service conditions, including: Extreme temperatures; High pressures; Abrasive particulates; Acidic products; Heavy solids build-up; Critical plant safety; Large pressure differentials; Velocity control; Noise control.

MOGAS valves have outperformed others worldwide in some of the most severe service conditions, including: Extreme temperatures; High pressures; Abrasive particulates; Acidic products; Heavy solids build-up; Critical plant safety; Large pressure differentials; Velocity control; Noise control.

Labels:

ball valve,

Connecticut,

Maine,

Massachusetts,

Mate Lap,

Mogas,

New Hampshire,

Rhode Island,

severe service,

Vermont

Happy Fourth of July from Piping Specialties

"America is much more than a geographical fact. It is a political and moral fact — the first community in which men set out in principle to institutionalize freedom, responsible government, and human equality."

Adlai Stevenson

Best Practices Document for the K-Patents PR-23-SD Safe-Drive™ Process Refractometer

This document is intended for individuals installing, commissioning, operating, and/ or servicing the Safe-DriveTM Process Refractometer PR-23-SD, generation 2.1 model. The purpose of this document is to provide a quick guide for the abovementioned tasks in the form of K-Patents recommended best practices.

This document is intended for PR-23-SD applications that have a steam wash system (typical application for black liquor) and applications that have high pressure water wash system (typical application for green liquor).

NOTE: These instructions are for quick reference only. For more thorough guidance, please refer to the K-Patents user manual and documentation that came with your equipment.

Review the embedded document below, or download a PDF version of Safe-Drive™ Process Refractometer PR-23-SD Generation 2.1 Best Practices here.

This document is intended for PR-23-SD applications that have a steam wash system (typical application for black liquor) and applications that have high pressure water wash system (typical application for green liquor).

NOTE: These instructions are for quick reference only. For more thorough guidance, please refer to the K-Patents user manual and documentation that came with your equipment.

Review the embedded document below, or download a PDF version of Safe-Drive™ Process Refractometer PR-23-SD Generation 2.1 Best Practices here.

Operating Principles and Application of Vortex Flowmeters

|

| Animation of vortices* |

Vortex flowmeters operate based on a scientific principle called the von Karman effect, which generally states that a fluid flow will alternately shed vortices when passing by a solid body. "Vortices" is the plural form of vortex, which is best described as a whirling mass, notably one in which suction forces operate, such as a whirlpool. Detecting the presence of the vortices and determining the frequency of their occurrence is used to provide an indication of fluid velocity. The velocity value can be combined with temperature, pressure, or density information to develop a mass flow calculation. Vortex flowmeters exhibit high reliability, with no moving parts, serving as a useful tool in the measurement of liquid, gas, and steam flow.

|

| Photograph of vortices ** |

Rangeability, defined as a ratio of maximum to minimum flow, is an important consideration for any measurement instrument, indicating its ability to measure over a range of conditions. Vortex flowmeter instruments generally exhibit wide rangeability, one of the positive aspects of the technology and vortex based instruments.

The advantages of the vortex flowmeter, in addition to the aforementioned rangeability and steam-specific implementation, include available accuracy of 1%, a linear output, and a lack of moving parts. It is necessary for the pipe containing the measured fluid to be completely filled in order to obtain useful measurements.

|

| Vortex flowmeter (Azbil) |

When properly applied, the vortex flowmeter is a reliable and low maintenance tool for measuring fluid flow. Frequently, vortex flow velocity measurement will be incorporated with the measurement of temperature and pressure in an instrument referred to as a multivariable flowmeter, used to develop a complete measurement set for calculating mass flow.

Whatever your flow measurement challenges, share them with a flow instrument specialist, combining your process knowledge with their product and technology expertise to develop effective solutions.

* Animation of vortex creation credit Cesareo de La Rosa Siqueira via Wikipedia.

** Photograph of vortices credit Jürgen Wagner via Wikipedia.

Labels:

Azbil,

Connecticut,

Maine,

Massachusetts,

New Hampshire,

Rhode Island,

Vermont,

vortex flowmeter

Providing New England Industry with Process Instrumentation, Valves, and Unsurpassed Service for Over 40 Years

PSI operates under one single mission: To provide specialty valves, instruments, control systems and mechanical products to industrial users throughout the Northeast, and to do so by providing unsurpassed customer service.

Covering the states of Maine, Vermont, Massachusetts, New Hampshire, Rhode Island, and Connecticut through offices located in Portland, Maine and Danvers, Connecticut, PSI is well situated to provide quick delivery, on-site services, and engineering support all through New England.

Piping Specialties, Inc. provides industrial valves, including ball, butterfly, gate, globe, safety relief, and control vales; and mechanical specialties including, steam traps, condensate recovery systems, steam water heaters, site level gauges, jet pumps, expansion joints, and modular pipe seals.

PSI Controls provides automated industrial and commercial valve packages that include quarter-turn and linear valves, pneumatic and electric actuators, limit switches and valve communications; and process instrumentation & controls including level, pressure, temperature and flow instrumentation.

PSI Services provides installation of valve automation systems, valve repair, instrument repair, instrument calibration, turnkey systems and field support services.

Covering the states of Maine, Vermont, Massachusetts, New Hampshire, Rhode Island, and Connecticut through offices located in Portland, Maine and Danvers, Connecticut, PSI is well situated to provide quick delivery, on-site services, and engineering support all through New England.

Piping Specialties, Inc. provides industrial valves, including ball, butterfly, gate, globe, safety relief, and control vales; and mechanical specialties including, steam traps, condensate recovery systems, steam water heaters, site level gauges, jet pumps, expansion joints, and modular pipe seals.

PSI Controls provides automated industrial and commercial valve packages that include quarter-turn and linear valves, pneumatic and electric actuators, limit switches and valve communications; and process instrumentation & controls including level, pressure, temperature and flow instrumentation.

PSI Services provides installation of valve automation systems, valve repair, instrument repair, instrument calibration, turnkey systems and field support services.

Floating Roof Tank Spill Prevention

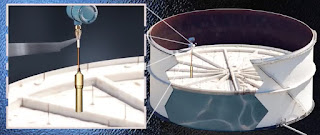

|

| Floating Roof Tank Spill Prevention (Drexelbrook) |

|

| Drexelbrook's Intellipoint |

The challenges to reliably detect a high level condition on a floating roof tank are long sensor length requirements, and the variability of what is being measured. The floating roof may be dry in which case you need to detect the position of the physical metal roof. Or there may be a few inches of rain water or petroleum liquids on the roof. Measuring instruments need to determine very accurately, usually within a few millimeters, when the position of the floating roof has reached a high level alarm condition.

Drexelbrook's Intellipoint, with its unique floating roof probe, can accurately detect and alarm on the position of the floating roof or the presence of liquid under all these conditions. The safety Intellipoint is a SIL2 fully certified RF admittance point level switch with uncompromising reliability for the most demanding applications. Drexelbrook has almost 60 years of RF admittance technology experience and is proud to offer this specialized product as the latest in its award-winning portfolio for the level market.

Product features include:

- Adjustable up to 15 feet, or 4.6 meters, to accurately control the alarm point.

- A trip point accuracy of a few millimeters.

- Fully SIL2 certified to IEC61508.

- Worldwide hazardous area approvals .

- Meets overfill protection standards API2350.

- A floating roof tank probe that is unique in the industry.

Refractometer Application for Wet Spinning of Alginate Fibers

|

| Refractometer used for wet spinning of alginate fiber. (K-Patents) |

The document below illustrates the use of industrial refractometers in the processing of Sodium Alginate. You can also download the full PDF of "Wet Spinning of Alginate Fibers" here.

Subscribe to:

Posts (Atom)