Piping Specialties Inc. (PSI) is one of the northeast's largest suppliers of valves; process controls/instrumentation, and engineered mechanical specialties. Industries served: Power Generation, Pulp/Paper, HVAC, Water/Wastewater, Food/Beverage, Life Sciences, Chemical/ Process, Semiconductor. For more information visit PSI-Team.com or call 800-223-1468.

The Emerson TESCOM™ Anderson Greenwood H2 Series for Hydrogen Applications and Fuel Stations

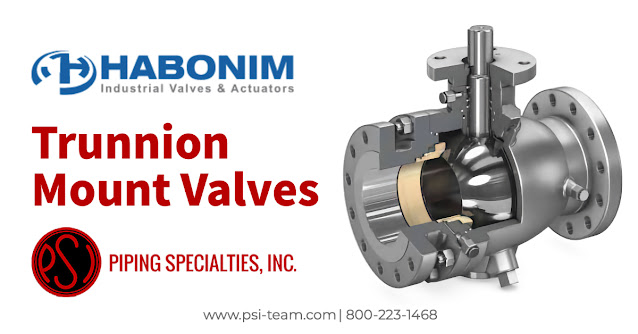

Trunnion Mount Valves

New Partnership in New England: Habonim Valves and Actuators

Habonim designs and manufactures floating, trunnion, cryogenic, high pressure, and metal seated ball valves. Additionally, they manufacture pneumatic actuators and complex manifold assemblies. Their products excel in the most demanding industries, including oil and gas, chemical, petrochemical, pharmaceutical, and mining. Habonim products comply with the strictest industrial and international standards with a constant focus on safety and environmental considerations.

Piping Specialties is pleased to partner with such a well-established and high-quality manufacturer.

Piping Specialties / PSI Controls

https://psi-team.com

800-223-1468