Piping Specialties Inc. (PSI) is one of the northeast's largest suppliers of valves; process controls/instrumentation, and engineered mechanical specialties. Industries served: Power Generation, Pulp/Paper, HVAC, Water/Wastewater, Food/Beverage, Life Sciences, Chemical/ Process, Semiconductor. For more information visit PSI-Team.com or call 800-223-1468.

The Emerson TESCOM™ Anderson Greenwood H2 Series for Hydrogen Applications and Fuel Stations

Level Measurement in the Food Processing Industry

Level sensors and controls are crucial in industrial food processing and production facilities to ensure quality and consistency. These devices monitor and regulate the level of liquids, solids, or granular materials in containers, vessels, or silos. Here are some of the most common types of level sensors and controls used in the industry:

- Capacitive level sensors: These sensors detect changes in capacitance caused by the presence or absence of material (liquid or solid) in a container. They measure liquids, powders, or granular materials levels in various applications, including food and beverages.

- Ultrasonic level sensors: Ultrasonic sensors use sound waves to measure the distance between the sensor and the material's surface. These sensors are non-contact and used for measuring levels of liquids or solids in tanks or silos and provide the food industry with accuracy and reliability.

- Radar level sensors: Similar to ultrasonic sensors, radar level sensors use radio waves to measure the distance between the sensor and the material's surface. They are also non-contact and suitable for liquid and solid materials. Radar sensors are particularly useful in challenging environments with dust, vapor, or foam, making them ideal for food processing applications.

- Hydrostatic pressure level sensors: These sensors measure the pressure exerted by the liquid column on the sensor at a specific depth. The pressure re-calibrates to a level measurement. They are primarily used for measuring liquid levels in tanks and have broad use in the food and beverage industry.

- Float level sensors: Float sensors use a floating device to detect the liquid level in a container. The float's vertical or tilting movement triggers a mechanical or electrical signal indicating the liquid level. Food processing plants often use them for simple and cost-effective level measurements.

- Vibrating or tuning fork level sensors: These sensors use a vibrating probe or tuning fork that changes its vibration frequency when it comes into contact with a material. They can detect the presence or absence of material and provide point-level detection of liquids, powders, or granular materials.

- Optical level sensors: Optical sensors use infrared or visible light to detect the presence or absence of a material at a specific level. They are suitable for various materials, including liquids, powders, and solids, in food processing applications where minimum contact with the material is essential.

The choice of level sensor and control system depends on factors like the process material, the required accuracy, the process conditions, and the specific application within the food processing facility. Each technology has advantages and limitations, so careful consideration is needed to select the most suitable option for each application.

Process Refractometers - The Vaisala Polaris™ Product Family

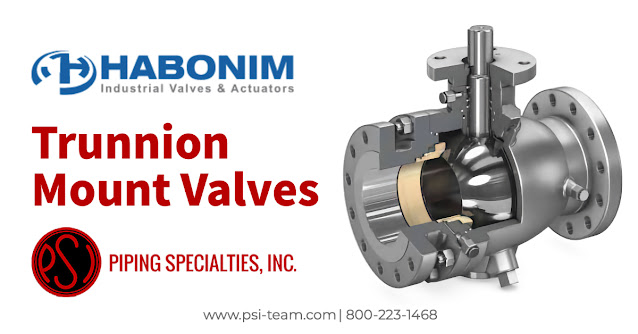

Trunnion Mount Valves

The Role of Metal Expansion Joints

- Lateral movement: Metallic expansion joints can accommodate lateral movement, which is movement in a side-to-side direction. This is important in systems that are subjected to thermal expansion and contraction, as the pipes will expand and contract due to temperature changes.

- Angular movement: Metallic expansion joints can also accommodate angular movement, which is movement in a rotational direction. This is important in systems that are subjected to vibration, as the pipes will vibrate due to the flow of fluid or gas.

- Axial movement: Metallic expansion joints can also accommodate axial movement, which is movement in a back-and-forth direction. This is important in systems that are subjected to misalignment, as the pipes may not be perfectly aligned.

- In addition to providing flexibility, metallic expansion joints also help to reduce noise and vibration, and they can protect against the effects of corrosion, erosion, and abrasion. They are often used in a variety of industries, including power generation, petrochemical, pharmaceutical, and food and beverage.

Cryogenic Ball Valves

- LNG (Liquefied Natural Gas) storage and transfer: Cryogenic ball valves are used to control the flow of LNG in storage tanks and transfer lines.

- Cryogenic tanks and vessels: Cryogenic ball valves are used to control the flow of cryogenic fluids in tanks and vessels used for storage and transportation.

- Refrigeration and air conditioning: Cryogenic ball valves are used in refrigeration and air conditioning systems to control the flow of refrigerants and other coolants.

- Industrial gases: Cryogenic ball valves are used in the production, storage, and distribution of industrial gases such as oxygen, nitrogen, and argon.

- Chemical and petrochemical processing: Cryogenic ball valves are used in the production and transportation of chemical and petrochemical products that require low temperatures for processing or storage.

- Aerospace and defense: Cryogenic ball valves are used in aerospace and defense applications to control the flow of cryogenic fluids in satellites, rockets, and other space vehicles.